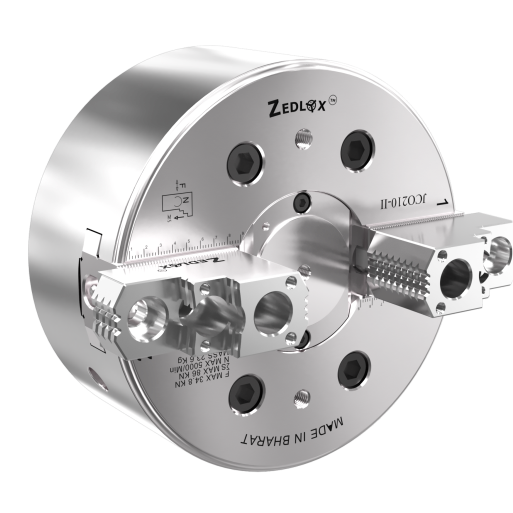

2 JAW LATHE CHUCK

2 Jaw Lathe Chuck Online | CNC Thru Hole Chuck Supplier India

The 2 jaw chuck is a specialized workholding tool designed for superior clamping of irregular and cylindrical parts. Unlike standard 3-jaw chucks, the 2 jaw lathe chuck offers flexibility in handling non-symmetrical workpieces with high precision. With a robust thru hole chuck design, it allows long bars, pipes, and shafts to pass through, making it ideal for machining operations that demand continuous workholding. Manufactured from hardened steel, this chuck ensures durability, reliability, and consistent performance across a wide range of machining tasks.

For advanced applications, the CNC 2 jaw chuck and precision thru hole power chucks provide stable clamping force, reduced vibration, and high machining accuracy. Workshops can enhance productivity with 2 jaw chuck accessories and replacement jaws, while industries handling heavy-duty components benefit from large thru hole chucks designed for industrial lathes. At the same time, smaller machine shops can choose a mini 2 jaw chuck for compact and precision work. The versatility and strength of this chuck make it a preferred choice for manufacturers across sectors.

As one of the trusted 2 jaw lathe chuck suppliers in India, we deliver high-quality solutions for both standard and customized needs. Customers can easily buy 2 jaw chucks online, request quotes, or check the 2 jaw chuck price list from our catalog. Whether you are a small workshop or a large manufacturer, our range of industrial 2 jaw chucks, CNC thru hole chucks, and hardened steel power chucks ensures the perfect fit for your machining requirements. With strong support, accessories, and after-sales service, we aim to be the best thru hole chuck supplier in India.

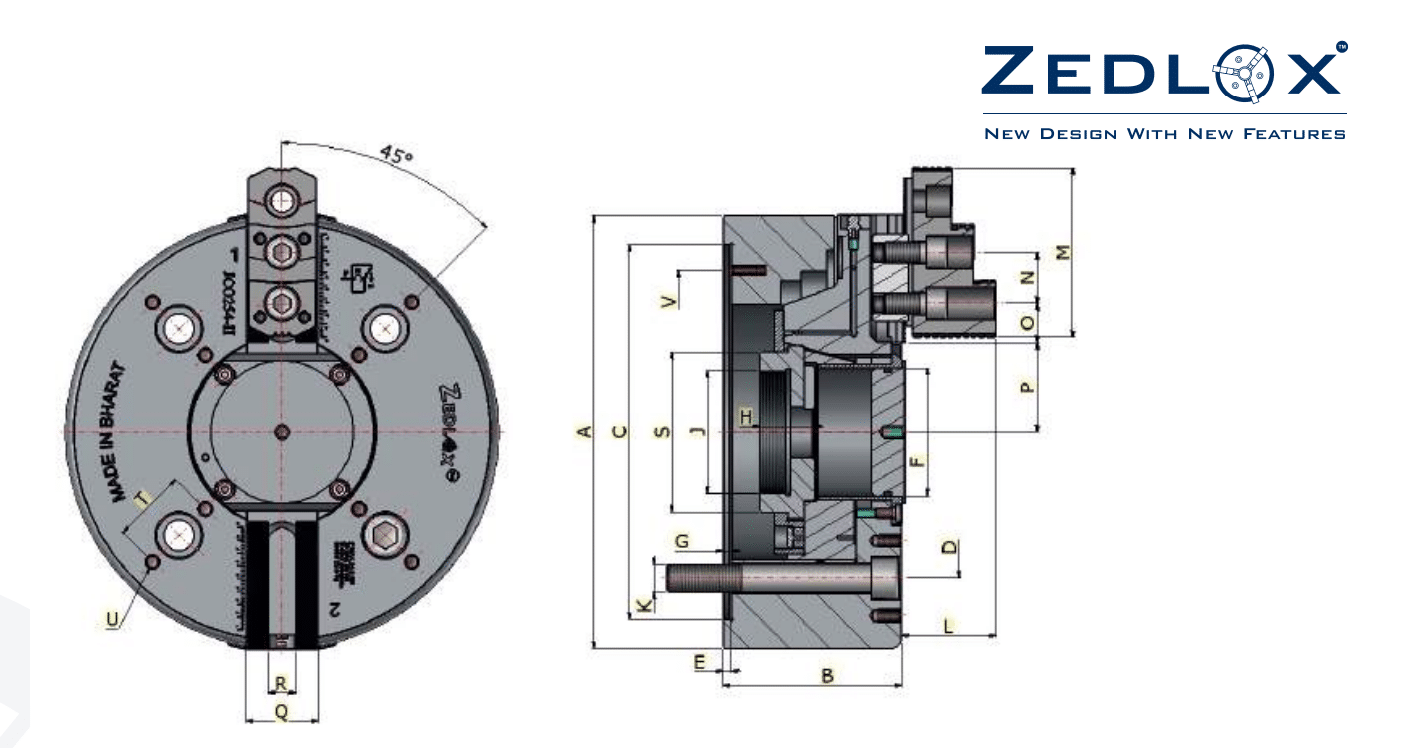

| Model | JC0170-II | JC0210-II | JC0254-II |

|---|---|---|---|

| Serration | 1.5×60 | 1.5×60 | 1.5×60 |

| A | 170 | 210 | 254 |

| B | 81.5 | 95 | 105 |

| C (H6) | 140 | 170 | 220 |

| D | 104.8 | 133.4 | 171.4 |

| E | 5 | 5 | 5 |

| F | 43 | 52 | 75.3 |

| G (Max) | 21 | 21.2 | 24.5 |

| G (Min) | 0.9 | 0.5 | 1 |

| H | 23 | 23.4 | 32 |

| J | M42×1.5 | M55×2 | M72×2 |

| K | M12×90 | M12×110 | M16×120 |

| L | 38.65 | 53.15 | 55.45 |

| M | 66.34 | 86.7 | 99.5 |

| N | 20 | 25 | 30 |

| O (Max) | 24 | 29.63 | 35.5 |

| O (Min) | 11 | 14.5 | 12.5 |

| P (Max) | 34.5 | 39 | 52.2 |

| P (Min) | 29.8 | 34.5 | 46.3 |

| Q | 32 | 37 | 42 |

| R | 12 | 14 | 16 |

| S | 59.8 | 67 | 94 |

| T | 17.5 | - | 43.9 |

| U | 4-M8 | 2-M8 | 8-M8 |

| V | 116 | 150 | 190 |

✅ Advantages & Benefits of Zedlox Power Chucks

-

Manufactured from high-grade alloy steel which extends chuck life while providing higher rigidity and greater wear resistance

-

For clamping round, square and geometrically irregular parts with precision

-

High rigidity structure and high clamping with micro-level accuracy

-

Long-lasting lubricating grease

-

Save valuable time with our user-friendly design

-

Quick and hassle-free installation

-

Long effective life and durability

-

Providing a large clamping force with slow attenuation for sustained and reliable performance

📦 Package Included

-

Chuck and mounting bolts

-

Soft jaws (1 set)

-

T-nuts (1 set)

-

T-nuts bolts

-

Key for chuck installations

-

Unhandled lantern spindle nut

🔹 Features of 2 Jaw Chuck

-

Precision-engineered 2 jaw chuck for secure clamping of irregular or cylindrical workpieces.

-

Available in 2 jaw independent chuck and CNC 2 jaw chuck designs.

-

Made from hardened steel for maximum durability and long service life.

-

Supports thru hole chuck for lathes, ideal for long bar and shaft machining.

-

Compatible with 2 jaw chuck accessories and replacement jaws.

-

Suitable for both mini 2 jaw chucks for small lathes and heavy-duty 2 jaw chucks for industrial lathes.

-

Provides stable clamping force with high accuracy for continuous operations.

🔹 Applications of 2 Jaw Lathe Chuck

-

Used in CNC machines and conventional lathes for turning, boring, and drilling.

-

Ideal for industries like automotive, aerospace, oil & gas, and heavy machinery.

-

Perfect for precision machining of square, rectangular, or irregular-shaped parts.

-

Widely used in heavy-duty thru hole chuck lathes for large workpieces.

-

A reliable choice for buyers searching to buy 2 jaw chuck online or from suppliers in India.

-

Supports both mini thru hole chucks for small lathes and large thru hole chucks for industrial workshops.